Aerospace projects completed at the CAMT CENTER

2018

Acronym: InnsLOT

Coordinator: Wroclaw University of Science and Technology

Partners: Pratt & Whitney Kalisz Sp. z o.o., Łukasiewicz Research Network – Institute of Aviation

Duration: 2018 – 2021

Funding: NCBR – TECHMATSTRATEG1/347514/7/NCBR/2017

Objective: The INNSLOT project aimed to develop a technological process using the additive method to produce thin-walled aircraft engine components using nickel alloy. The project was carried out by a consortium whose leader was the Wrocław University of Technology with over 20 years of experience in the field of additive technologies; Pratt & Whitney Kalisz Sp. z oo – producer of aircraft engines parts and Łukasiewicz Research Network – Institute of Aviation (Warsaw, Poland) – a research unit

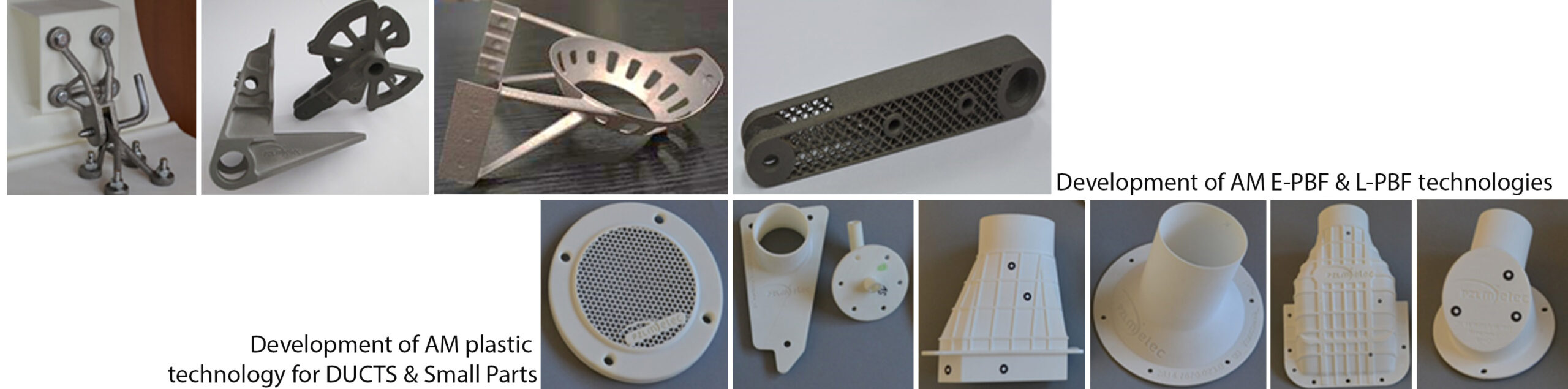

As part of the project, a manufacturing process was developed and tested using the SLM / LPBF method (following ISO/ASTM 52900:2019, the PBF-LB/M method – Powder Bed Fusion – Laser Beam / Metal) and the Inconel nickel alloy most commonly used in aviation 718, used, among other things, for the production of thin-walled steering apparatus. The task of the steering apparatus is to manage the gas stream flowing through the turbine engine. Steering devices are used in aircraft engines’ compressors (cold end) and the turbine (hot end). One of the specializations of Pratt & Whitney Kalisz is the production of steering apparatuses.

During the project, a technological process was developed, including powder material management (input to the additive process), additive manufacturing process (PBF-LB / M), annealing, heat treatment, finishing surface treatment, and a quality control process. The developed course of the manufacturing process allows to obtain high-quality parts, characterized by static and fatigue strength appropriate for the application and meets the requirements related to geometric accuracy and surface quality on the gas path, which are imposed on real steering devices.

2017

Acronym: AMgAvio

Coordinator: Wroclaw University of Science and Technology

Duration: 2017 – 2019

Funding: NCBR – program LIDER 0109/L-7/201

Objective: The project aimed to develop processing of magnesium alloys for aerospace applications by SLM/DMLS (Selective Laser Melting / Direct Metal Laser Sintering) technology. During the project, the potential of obtaining in SLM process magnesium alloys with high mechanical properties, at least close to that obtained for conventional ones, was evaluated.

2013

Acronym: AMpHOra

Coordinator: PZL Mielec (a Lockheed Martin Company)

Duration: 2013 – 2018

Funding: NCBR, INNOLOT/I/6/NCBR/2013

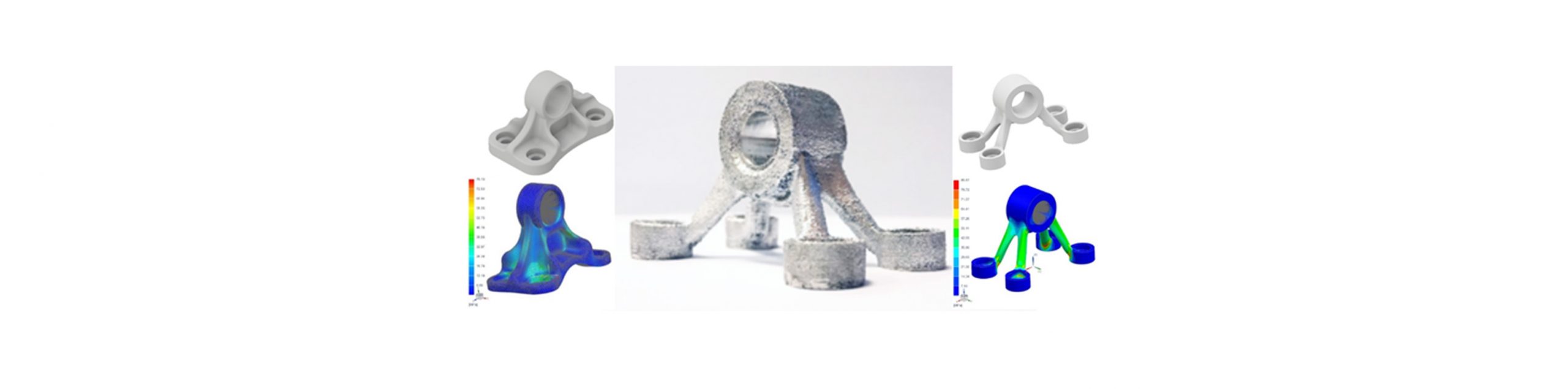

Objective: The objective of the project was the development of methods for designing and manufacturing of aircraft components with additive technologies. The results of the research will contribute to the implementation of the AM methods allowing for weight reduction of aircraft parts while maintaining or improving their strength, which in the end will improve safety and reduce fuel consumption, essential for reduction of environmental pollution.

Acronym: DRILL

Coordinator: WSK “PZL-Rzeszów” S.A.

Duration: 2013 – 2015

Funding: współfinansowany przez NCBR w ramach programu INNOTECH (INNOTECH-K2/IN2/46/182494/NCBR/13)

Objective: The project aimed to develop the laser-cutting technology of angular holes in aircraft engines’ multilayer materials combustion chambers. The other aim of the project was to improve the stability and geometric accuracy of their location. The developed technology will allow laser drilling of angular holes in multilayer materials with thermal barrier coatings (TBC) and anti-spatter coatings.