Industry 4.0 projects implemented in the unit

2024

Coordinator: Politechnika Wrocławska

Partner: Brandenburg University of Technology (BTU)

Duration: 2024 – 2026

Funding: Bilateral grants from the National Agency for Academic Exchange (NAWA)

Objective: Additive manufacturing (3D printing) and, more specifically, selective laser sintering (SLS) is gaining importance as an alternative manufacturing method. This applies in particular to the use of polyamide 12 (PA12) in SLS technology, due to its mechanical properties and ease of processing. However, the challenge is to reuse material in this process, which accumulates in subsequent cycles. This is problematic both economically and ecologically.

As part of the project, detailed research will be carried out on the mechanical properties and microstructure of parts made of mixtures of fresh, used, and recycled materials. The project team plans to focus on understanding the phenomena that occur during static and cyclical loads for this type of elements and trying to describe them with selected numerical models

2023

Acronym: DEETECHTIVE

Coordinator: Wroclaw University of Science and Technology

Partners:Holon Institute of Technology (Israel), Universita di Genova (Italy), EPF School of Engineering (France), Centria University of Applied Sciences (Finland), Institute of Technology Transfer (Poland)

Duration: 2023 – 2024

Webpage: https://www.deetechtive.eu

Funding: EIT RawMaterials

Objective: As part of the DEETECHTIVE project, an innovation support model will be developed and implemented, involving the transformation of participating universities into universities with a significantly increased capacity for entrepreneurship and innovation and an increased impact on the surrounding ecosystems. DEETECHTIVE’s unique approach focuses on open innovation, the sharing economy, and community-based product development. The implementation of seven dedicated innovation support activities, presented in the diagram, will focus on “deep tech”, including: advanced materials and manufacturing, artificial intelligence and machine learning, photonics, robotics and Web 3.0.

Acronym: SMERF

Coordinator: Wroclaw University of Science and Technology

Partners: (1) Business Upper Austria, Mechatronics Cluster (Austria), (2) Center of Research and Technologic Innovation s.r.l. (Italy), (3) Karlsruhe Institute of Technology (Germany), (4) Pannon Business Network Association (Hungary), (5) STEP RI Science and Technology Park of the University of Rijeka (Croatia), (6) University of Genoa (Italy), (7) Technical University of Kosice (Slovakia).

Duration: 2023 – 2026

Webpage: https://www.interreg-central.eu/

Funding: Interreg Central Europe

Objective:

The project focuses on developing models and tools to effectively support the transformation of low- and medium-technology SMEs towards readiness for future challenges. In addition, the project aims to develop new models of services for universities and services supporting the innovation of business environment institutions. This will allow them to increase their competencies and opportunities to support SMEs on the path to transformation. The main goal of the SMERF project is to conduct research on the development of models, tools, and services supporting the transformation of SMEs in four pillars:

- Culture of innovation.

- Digital production.

- Open Innovation 2.0 and the sharing economy.

- Green circular economy closed and sustainable development.

2022

Acronym: PowderEUse

Coordinator: Wroclaw University of Science and Technology

Partners: 3D Bistro, Zakład Badawczy Przemysłu Piekarskiego (ZBPP) oraz Fraunhofer Institute for Machine Tools and Forming Technology

Duration: 2022 – 2024

Funding: M-ERA.NET Call 2021 / NCBR

Objective: Selective laser sintering (SLS) is an additive manufacturing technology, also known as 3D printing, where a polymer powder is added layer by layer and then melted by a laser beam. The feedstock material in the SLS is mainly polyamides, which represent more than 90% of the market today (polymer powder market reached $539m in 2019). During the production process, only about 10% of the volume of the working chamber is used, and the main drawback is the inability to directly reuse the material because of chemical changes due to thermal degradation. The goal of the project is to demonstrate the ability to regenerate waste powders in SLS and obtain ready components with acceptable characteristics, while reducing costs for short production runs. This solution is primarily a new approach in the field of environmental protection, which allows the elimination of post-process waste to a large extent and is an important aspect in the industry in prototypes and tooling production, consumer goods.

2019

Acronym: Level 4.0

Coordinator: Wroclaw University of Science and Technology

Partners: Wroclaw University of Economics and Business, Wroclaw Technology Park, Balluff Sp. z o.o. and TestArmy Group S.A.

Duration: 2019 – 2021

Webpage: htttp://www.level4dih.pl/

Funding: Ministry of Economic Development, Labour and Technology

Objective: The project’s primary goal is to support organizations and enterprises in increasing market competitiveness by implementing innovative solutions and the most modern technologies of Industry 4.0..

Specialization of Level 4.0 | Digital Innovation Hub Wrocław is additive manufacturing technologies, industrial automation, technical and management education, cybersecurity, and business innovation..

Acronym: PRE-IN-POST

Coordinator: Wroclaw University of Science and Technology

Duration: 2019 – 2021

Funding: NCBR, Lider, 0071/L-9/2017

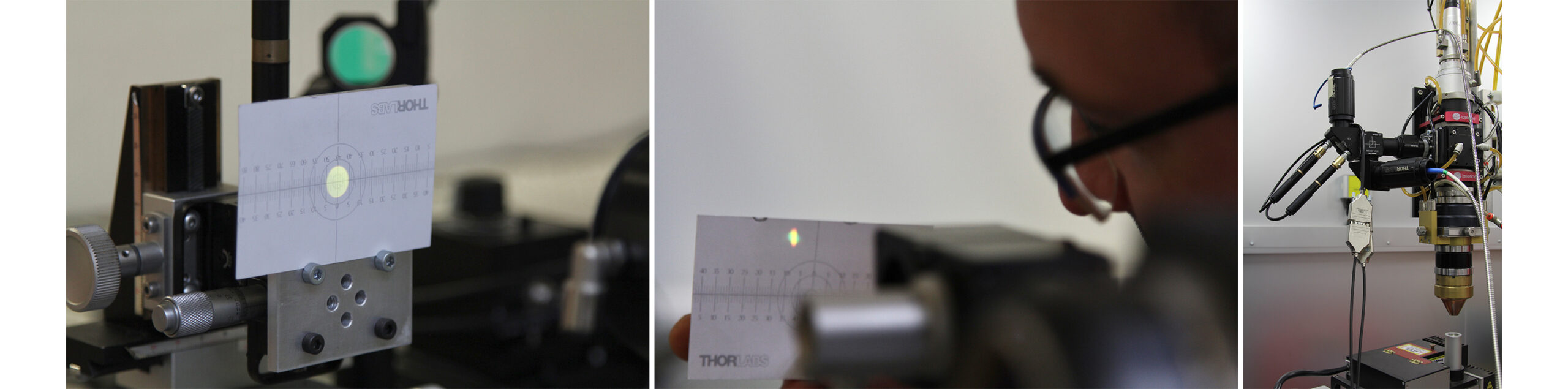

Objective: The research conducted as part of the project will allow the development of a system for process control of material processing with a laser beam using chromatic aberration. The system will be implemented in the laser head and demonstrate functionalities that are not available in the methods commonly available on the market. The proposed solution will meet the assumptions of the PRE-IN-POST concept. Before the laser process – it will allow to adjust the position of the laser head nozzle concerning the substrate. It will determine, during the process, the height/depth of the material processing effect with the laser beam without using a reference beam. After the process – it will allow you to draw the front profile of a laser-processed element.

2017

Acronym: AMABLE

Coordinator: Fraunhofer Institute for Laser Technology ILT (Germany)

Partners: Wrocław University of Science and Technology is a member of the consortium consisting of 21 organizations. The complete list of consortium participants is provided on the CORDIS Europa website (https://cordis.europa.eu/project/id/768775/pl).

Duration: 2017 – 2021

Webpage: https://www.amable.eu/

Funding: Horyzont 2020 – H2020-FOF-2017, No 768775

Objective: EU SMEs/mid-caps face clear barriers in the uptake of Additive Manufacturing (AM) related to lack of skilled human resources, and lack of access to know-how, equipment, infrastructure and markets. The principal objective of this project is to overcome those barriers and enable the uptake of AM technologies by SMEs/mid-caps leading to the development of innovative business and service models and new value-chain models in a fully digital environment – thus bringing their ideas and business cases to life and making their innovations Additively Manufacturable (AMable).