Acronym: DiAlForm

Coordinator: Bydgoski Klaster Przemysłowy

Partners: Fraunhofer IWU, Fraunhofer IST, Politechnika Wrocławska

Duration: 2022 – 2024

Funding: CORNET 31

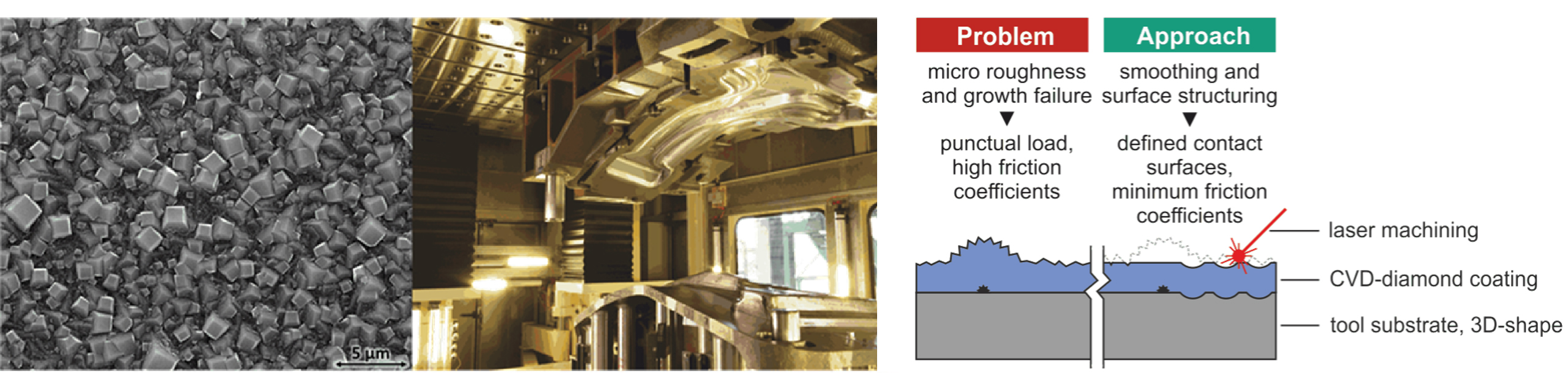

Project description: Technology enabling the application of HF-CVD diamond on forming tools in combination with a local surface conditioning of the tool active part surfaces by means of laser processing.

Acronym: AddAluMat

Coordinator: Wrocław University of Science and Technology

Duration: 2022 – 2025

Funding: NCBR – XII Program Lider

Project description: The project will develop a technology for processing functional aluminum alloys (series 5xxx) using additive laser powder bed fusion (LPBF) technology and potential application of additives to aluminum alloy powders to achieve a uniform structure of processed objects used in a wide range of industrial applications. A selected demonstrative part from a chosen industry (e.g., automotive and/or marine) will undergo topological optimization and will be produced using LPBF technology. Parts manufactured from these alloys can be used as production parts as well as spare parts.

Acronym: –

Coordinator: Wrocław University of Science and Technology

Duration: 2021 – 2022

Funding: National Science Centre, Miniatura 5

Project description: The main goal of the project is to produce an in-situ titanium matrix nanocomposite reinforced with titanium diboride particles using additive technology – Electron Beam Melting (E-PBF).

Acronym: –

Coordinator: Wrocław University of Science and Technology

Duration: 2021 – 2022

Funding: National Science Centre, Miniatura 5

Project description: The aim of the project is to determine the relationship between process parameters and the structure and properties of the TZM alloy processed using SEBM. Based on the developed relationships, it will be possible to achieve specific processing results for the alloy (specific microstructure, degree of porosity, etc.) within the accepted range of selected process parameter variability.